Why hard maple? For one, it’s hard. (Hence the name…) It is dense enough that the fibers of the wood can hold up to the constant turning of the tuning pins. Using a wood that is too soft will wear the threads in the pinblock holes prematurely and fail to hold the pins in place.

“All right, I’ll get a piece of ebony and make the ultimate pinblock!”

Hold on. Besides being needlessly expensive, there’s more to it than just hardness. Consider a pinblock’s function: we’ll be drilling twenty five 3/16″ holes in our pinblock, (essentially turning the pinblock into swiss cheese), and threading all 25 tuning pins into it. The threads on a tuning pin are very shallow, and the hole is of course drilled slightly undersized to account for these threads.

Maple has just the right “give” to slightly expand and help grab the pin as it is being driven in. With denser woods, some are so absolutely stubborn that there is almost no “give” at all, and a bigger hole has to be drilled to avoid cracking the wood. There is much less forgiveness in regards to hole size with some of the super-dense woods.

And as a side-note, if you do end up using a very dense wood for the sides of your psaltery, (which is perfectly acceptable), you’ll want to drill slightly oversized holes for the hitch pins to avoid splitting the sides. The pinblock of course should still be made of hard maple and drilled with 3/16″ diameter holes.

Another thing to take into account is the grain and porosity of the wood. Hard maple has very fine and even pores, which help maximize the actual amount of wood that is in contact with the threads of the pin.

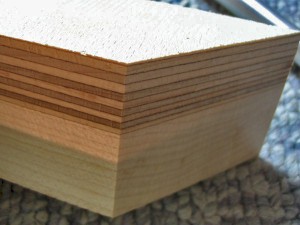

Taking this one step further, some piano manufacturers even use pinblocks of laminated hard maple, sort of like a specialized plywood (one brand-name in Germany that uses Beech is Delignit). These pinblocks are made of very thin laminations of maple or beech to ensure complete evenness and consistency throughout the block; though, we will achieve no such fineness here!

But one thing to consider is this: if you can’t find hard maple in a 1.5″ thickness, there is absolutely nothing wrong with gluing two or more thinner pieces together to reach the full thickness. (Just be sure that the layers are stacked horizontally, not vertically. Otherwise, a tight tuning pin might split the layers apart.)

Another point is what I would call wood “oiliness.” Some woods are dense, but they are also very oily too, especially rosewoods. This would seem to suggest that they would be more prone to slipping, or maybe even the opposite with some woods – sticking if the pins get gummed up with tree resins. Also, many darker woods have a high amount of tannin, which may cause premature corrosion of the tuning pins as well. (This is not as big of a deal for the sides of the psaltery because the pins in the side are stationary and do not use the threads to adjust anything.)

Also, there is the matter of moisture content. Pinblock wood should be dry. Here’s a shot at perhaps one of the densest and heaviest of woods, Lignum Vitae:

That wood has literally twisted nearly 90 degrees to one side after it was cut. Imagine what would happen to a finished instrument if wood this unstable was used for the pinblock. The general rule of thumb on freshly cut lumber for air-drying is to wait one year per inch of thickness. (Or just buy lumber that has been dried for you.)

All this to say: I highly recommend using hard maple for your pinblock. This wood, from the tree Acer saccharum, goes by many names: hard maple, sugar maple, or rock maple. If you are buying maple,I would make sure that it is specifically hard maple, by either one of the three names listed above, as there are many types of soft maples commonly available as well, and can easily be confused.

Now, I recognize that some will be making this on a shoestring budget, and not everyone will be able to get a piece of hard maple in all situations. So, if whatever reason you can’t/won’t buy a hard maple pinblock, here are some alternatives: if you are in Europe, then European Beech is an excellent choice, and is probably the European equivalent to hard maple. (Some even consider it superior to hard maple.) American Beech is also nearly identical to European Beech.

Otherwise, other domestic species that can work with varying degrees of success are ash, walnut, and red or white oak. (If in doubt, you can give it the fingernail test – try gouging your fingernail into an edge of the board and see if it leaves a nick. Hard maple is practically invincible to this – at least, on my fingernails anyway!)

I would say though, please, for your own sake, avoid using woods on the extreme ends of the hardness spectrum for the pinblock! On the soft side, stay away from pine, cedar, redwood, fir, spruce, and other softer hardwoods like aspen and poplar. On the harder side, avoid the extremely hard and “stubborn” exotic hardwoods that may very well crack if given only 3/16″ diameter holes for the tuning pins; these woods include: bloodwood, ebony, and most rosewoods. That’s all I will say on this subject.